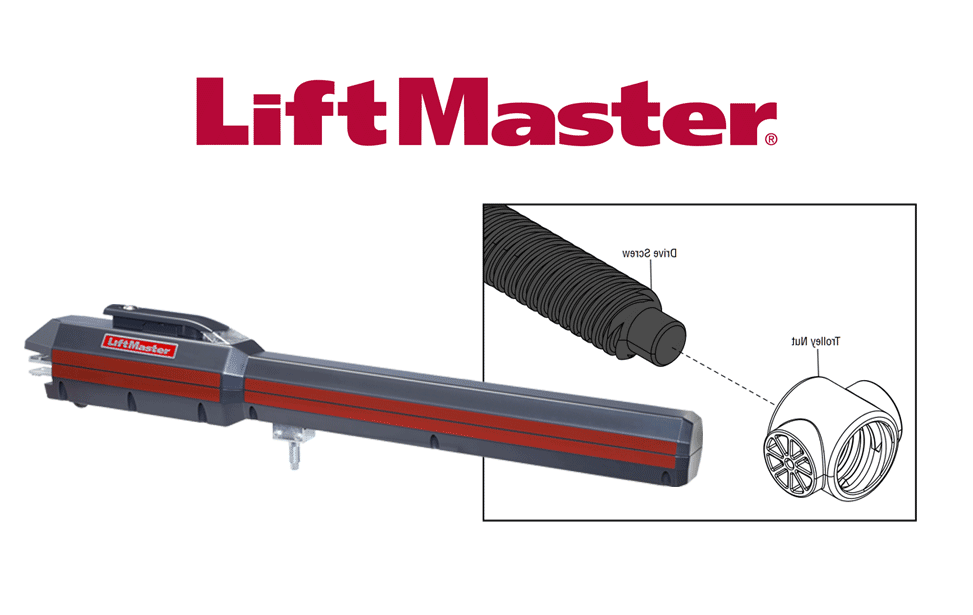

The travel nut on LA500DC and LA500DCS gate operators may break when excessive force is applied to the gate, such as being struck from a vehicle. The travel nut can be identified as the white plastic nut that attaches to the internal lead screw of the arm. The symptom of this problem is that the trolley assembly slides back and forth along the guide slots without mechanical restraint. The broken part can be observed through the guide slots on the bottom of the arm.

LiftMaster has created the K75-39337, Trolley Service Kit with all the necessary parts and provides instructions on how to replace a damaged travel nut within an LA500 arm. LiftMaster advises the travel nut replacement to be conducted in a controlled environment such as on a bench in a workshop, due to its complexity and the opportunity of dirt/debris being trapped within the transmission of the arm.

Powerful, long-lasting, and low-maintenance automation solutions